SIGA – Integrated Asset Management System – is an initiative for the digital transformation of the asset management service aimed at productivity gains in field inspections, identification of anomalies/pathologies and a reduction of up to 25% in unnecessary expenses for our customers with maintenance costs, considerably increasing the quality of engineering deliverables (products) extracted in real time from the BIM model of the asset loaded into the solution.

In 2019, there were about 137 thousand OAEs spread across Brazil, and Concremat estimated that at least 1200 of them needed immediate interventions at a structural level. The lack of maintenance or incorrect maintenance causes serious events that, in addition to victims, generate problems in all urban mobility for months or even years, wasting millions of reais in emergency contracts.

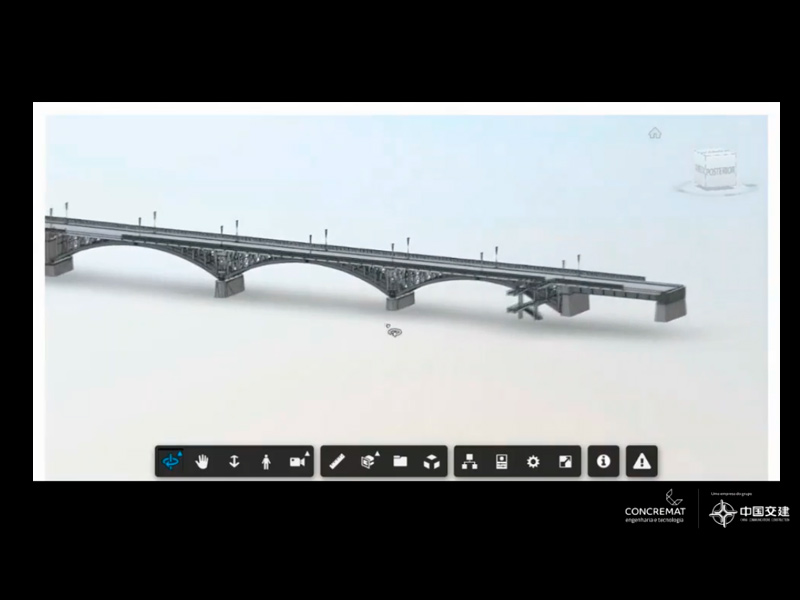

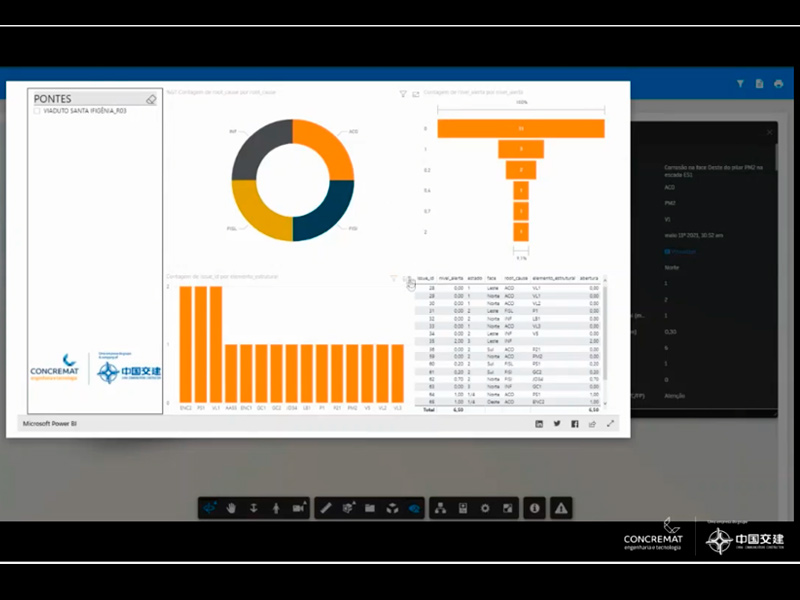

Aimed at special works of art, SIGA-OAE is the product that started SIGA’s journey into the engineering market. The product has been applied in contracts with public and private customers, providing a dynamic way to consult information about the asset, whether by level of criticality, category, element or even by the portfolio of assets, also promoting the isolated visualization of elements, sections , assets and set of assets.

Crossing laser scanning (to capture existing OAE conditions), orthophotos, original designs and other field surveys, a BIM Digital Twin model is created. It is through all this information that SIGA-OAE incorporates the managed data of each structure and, through mobile devices, small field teams carry out inspections and position details to update the software with anomalies in all the main elements of the structure. From that point on, the entire management of the anomaly is carried out in the system, which controls everything from identification to post-maintenance inspection, validating solutions, budgets, calculation memories, etc.

The solution was based on studies and implementations of the BIM model at Concremat that took place since 2012. Its conception was leveraged after the implementation of the BIM methodology in the area of studies and projects and the conclusion, in 2019, of the InfoMap RD&I. Allied to Concremat’s trajectory with the use of BIM, the main factor was the need for evolution in the inspections of OAEs throughout the country, mainly in their control flow. The project started effectively in 2020 with the adoption of laser scanning and the creation of the BIM model together with the Digital Twin studies of the structures.

The control base has a mix of internal development, Concremat’s own solution and an unprecedented open innovation in Latin America, in direct partnership with Autodesk through FORGE applied to engineering solutions. The product is constantly evolving and will soon incorporate the application of Artificial Intelligence and Machine Learning for greater control and advanced analysis of structural behavior, enabling preventive and predictive maintenance.